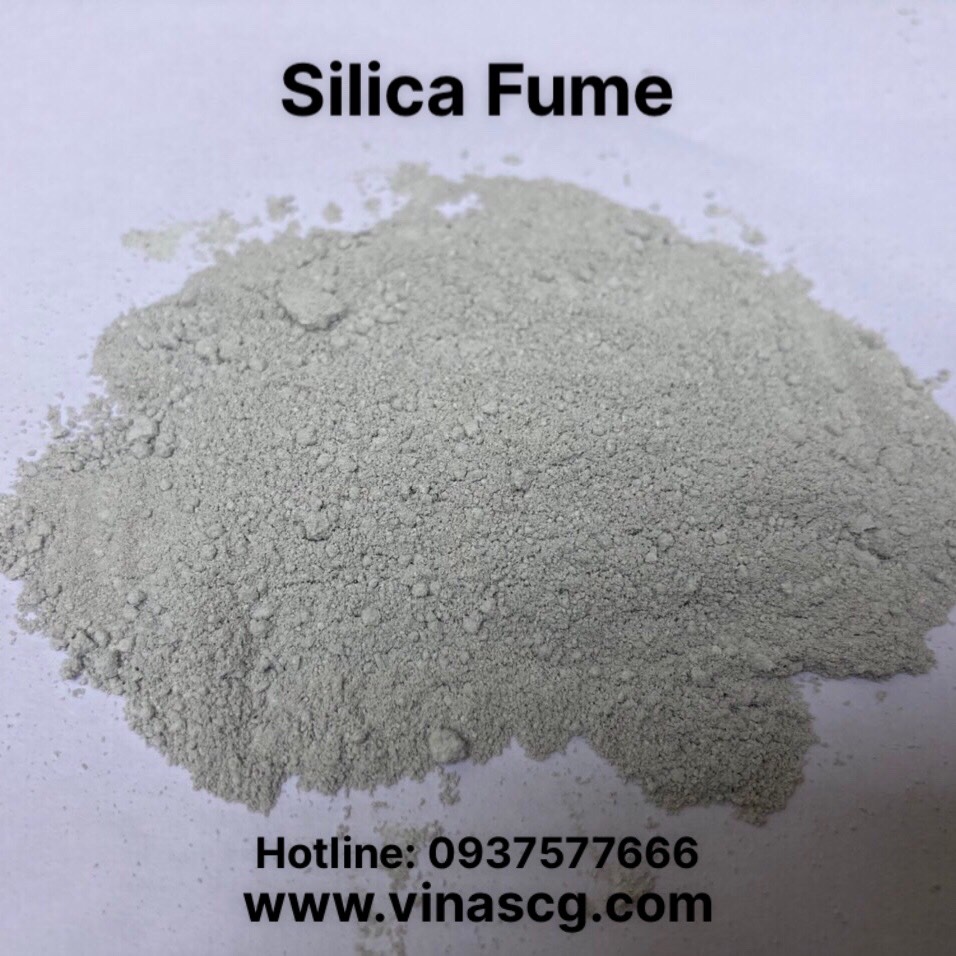

Sillica fume/Microsilica

Ingredient

The condensed silica consists mostly of pure silica in the form of non-crystalline form and contains more than 90% of silicon dioxide. Small amounts of magnesium, iron and alkaline oxides are also present. Most particles are smaller than 1 mm with an average diameter of 0.1 mm. ASTM C 1240 percentage limits are retained on a 45 mm to 10% sieve, moisture content is 3% and ignition loss (LOI) is 6%.

Replace

Condensed silica is used as an alternative to portland cement. Silica fume can replace portland cement in about 9-15% by weight of cement.

Advantages

– Improve the relative durability of concrete by significantly reducing the permeability of concrete;

– Increase early strength and eventually both compression and bending;

– Extremely high strength concrete exceeding compressive strength of 15,000 psi and elastic modulus of 6,000,000 psi;

– Increasing resistance to strong chemicals up to 15 times higher than ordinary concrete;

– Increase the density;

– Reduce damage due to freezing and thawing;

– Increase the abrasion resistance of concrete;

– Reduce surface bleeding;

– Effective corrosion inhibiting system against the ingress of salt contaminants generated in water (reducing salt or sea salt);

– Reduce discrimination;

Although CSF is primarily strength, it also provides other durability related properties. In pipelines, the addition of CSF is shown to be the bearing capacity of the pipes by being used to increase concrete advantages such as improving concrete production which increases external load by 40%. The resistance of pipes against chemical attacks is also greatly increased. Concrete pipes containing only about 5% CSF have a 2-3 times longer lifespan than conventional pipes when exposed to sulfate. Concrete containing CSF is known to improve its defenses against defrosting, chloride penetration and descaling, making it useful for road construction. In addition CSF also increases the abrasion resistance of concrete, especially at higher dosages. A 20% dose of Corrocem, a proprietary mixture based on CSF as the main ingredient, shows 3O-35% higher abrasion resistance than good quality concrete. Due to reduced permeability and lower free lime content in cement powder, CSF concrete is considered to be highly resistant to chemicals.

SILICA FUME (often called Silica) , also known as microsilica

is a gray silicate activated silica powder capable of reacting with Calcium Hydroxide (solute) in the hydration process of cement to create Calcium Silicate Hydroxide form of insoluble crystalline structure to increase solidity and resistance permeate and increase the life for concrete. It has superfine size (size is less than 100 times the size of cement particles), can fill holes in concrete structure that cement particles cannot fill.

Application

– Mainly used in concrete aiming (mixing 90s):

• Increased durability for concrete, construction,

• Reach high intensity early,

• Increase the final intensity,

• Increased resistance to abrasion,

• Increased resistance to sulfate,

• Significant increase in water resistance,

• Improve workability,

• Increased resistance to gas penetration significantly,

• Minimize the diffusion of chloride.

– Used to fill and seal oil wells,

– Used as refractories.

Pack

+ 20Kg-25Kg / bag

Origin

+ Chinese / Vietnamese

Other names: Silica Fume, concrete additives, cement additives, construction additives, Silicafum, microsilica …

Contact:

SCG VIETNAM JOINT STOCK COMPANY

Address: No. 03, lane 342/29 Ho Tung Mau street, Bac Tu Liem District, Hanoi City

Email: scg.vietnamjsc@gmail.com

Price: Negotiable (best price in the market)

Contact: Mr Thanh 0937577666/0986160999

1 review for Sillica fume/Microsilica

Show reviews in all languages (2)

Anonymous –